Fall 2023

The up side of my new art adventure are the many mediums to play & create with. The downside is that it’s mostly done in huge, un-airconditioned spaces which in Florida can be a both sweaty and stinky.

Sculpture is a pretty broad term which covers art in three dimensions. I didn’t know what I expected when i signed up for class at UNF. What I found was energizing. Even tho’ I take pride in being an indoor girl, I think I’m going back for another class next semester. I really like it – except on days where I’m on my feet for hours because I get lost in my right brain. The program supports everything from small student structures to large public art that is installed around campus, as well as in parks and public venues around Jacksonville. Click to visit UNF Seaside Sculpture Park to see some of the students work. Or, if you’re local, head to the beach and see it in person

It started with plaster

I was two weeks late for the start of class and had to catch up. Right away, the first assignment was dumping 40 lbs of plaster into 5 gallons of water one handful at a time. Fast forward a week, I now have an 80lb block in a bucket that needs to dump upside down. IT WAS HEAVY. Luckily, the class is full of people willing to help. The gallery below shows the progression from roughed out block to final sculpture.

Fire followed plaster.

This metal-forward program seems to be driven by fire. I’m generally not a fan, but I’m trying to get over it. Melting metal in many forms is what happened over the rest of the semester. Oxy/acetylene welding torches were first so we could understand how to get the metal flowing. In my case, I opted for using capillary action (on copper) vs the more brute force melting two pieces of metal together with a third one using the oxy/acetylene torch.

Metal Inert Gas (MIG) welding came next. Welding is trade where apprentices practice honing their skill over time. These skills need to build up to some extent before you can successfully put the ‘art’ on top. As a confessed art hacker, the time and skill necessary to craft metal objects seemed to be a little at odds with my ‘just do it’ style of art. However, they do say that MIG welding is the hot glue gun of the metal world. So, I practiced by picking up discarded pieces of pencil steel from the shop floor and ‘glued’ them together ala abstract 3D. I think the result looked a lot like Lance, the instructor. In spite of my lack of skill and fear of fire, I had fun making stuff. Many of the welds I made are still holding up weeks later – lol if you don’t do it right, they break apart…oops. The pictures of the projects that flowed out of this fire phases of fire were: 1) copper bottles – these were soldered, not welded. They are technically two different things that are both accomplished with the Oxy/Acetylene torch. 2) The Portrait of the Instructor and 3) a Spring(ing) Flower. The last two were both MIG welding projects.

Cast iron came next

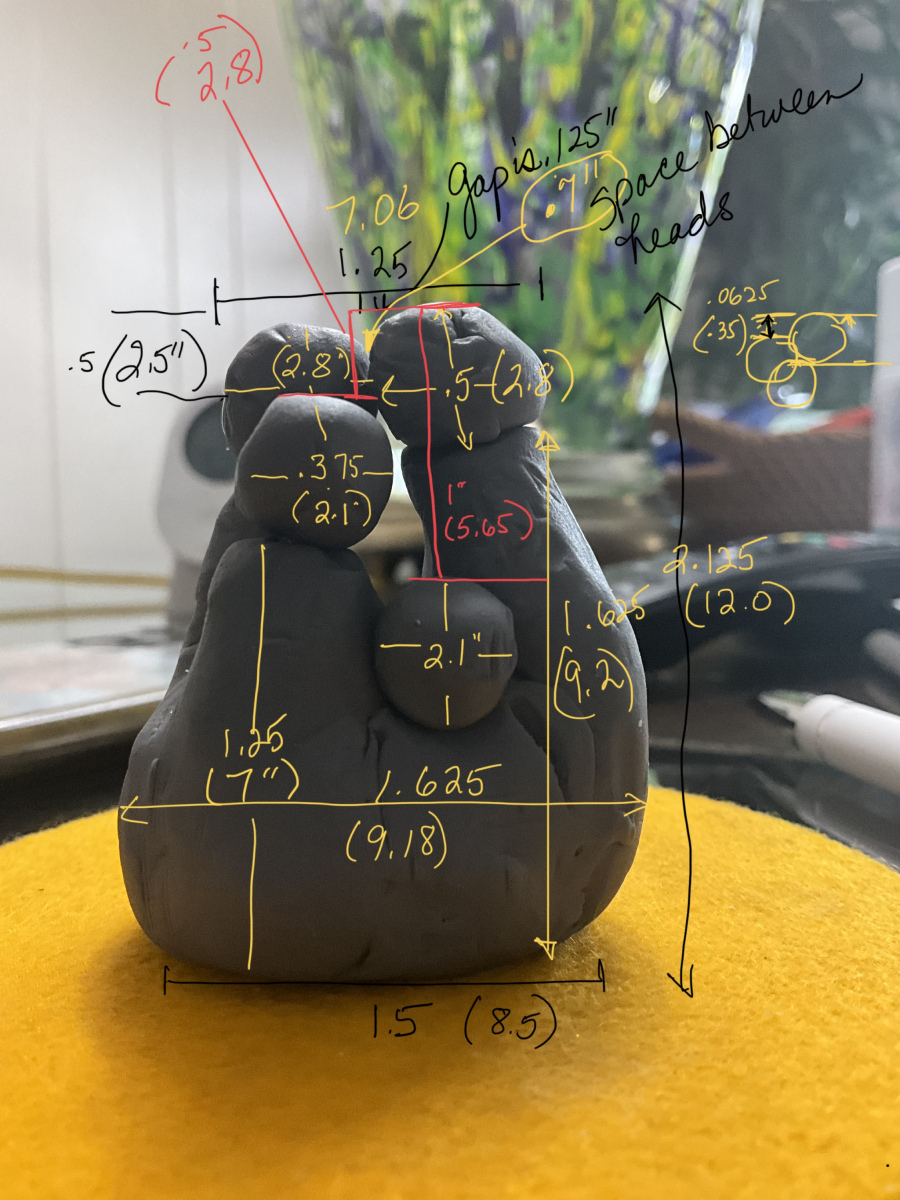

Twice a year at UNF, all the sculpture classes get ready to pour iron. 3-D students as well as members of the general public made a one part mold called a scratch block. In Sculpture 1, we got to make a two part sand mold. This was done the traditional way with flasks and follow boards and epoxy resin mixed with sand. You basically build two separate halves of resin-hardened sand around your ‘pattern’ (the thing you want to cast). Once the first side hardens, you flip it over to pack in the second side. You then take the ‘pattern’ out, leaving a void in the middle that gets filled up with liquid metal.

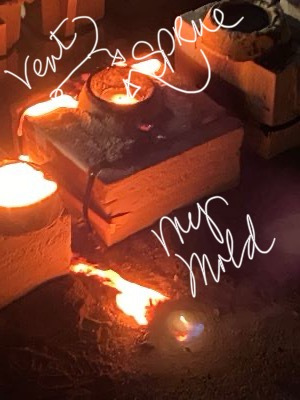

Molten metal is very very hot, but cools very, very rapidly. To improve your chances for success, you have to put vents in so the air can be pushed out by the rushing metal, and gates in to help quickly move the cooling metal into every part of the mold. The sprue, or hole where the metal goes in, gets covered with a cup, and sealed up to await the big day. BUT… where does cast iron come from? Each sculpture class participating in the iron poor had to break up recycled sinks and bath tubs and other discarded iron pieces down into taco-chip sized pieces with a sledge hammer. As well as breaking up enough coke to liquify all that metal. You bag them up in chunks weighted amounts that can be dumped directly in the furnace. On the day, the pre-measured bags are alternately dumped directly into the furnace to charge it. There are teams of people charging the furnace, making sure that the gook all melts down, drawing a bucket of hot iron to carry to the molds and the mold master that directs the pouring into the molds. It literally took a village of people all dressed in leather safety gear (jackets, aprons, chaps, spats, gloves, boots, face mask and hard hat) while local spectators looked on.

After the Iron Pour and associated unmolding, there was a significant amount of iron waste to remove to find the final piece. Cutoff wheels on the grinder made quick work of the gates and sprue but the tiny bits along the part line, where the two halves of the mold meets, needed some (or much) touching up. Unknowingly, I drilled a gate right in the wings of one of the birdies, oops. The Iron Pour assignment was to make a mixed media piece. The first piece was a ‘found object’ which we would use as a pattern to cast in iron. The rest of the mixed media piece was up to us. My patterns were two little wind-up birds and a stuffed toy banana shown in the photos below.

After a touch of paint, the birds were added to a driftwood branch. I used oil paint markers to color in order to try and minimize the rust. Time will tell. The bird sculpture is titled “Who Flew”. The banana sculpture it called “Cuckoo for Cocoa Puffs”.